Plastics have only been around for a little over a century, yet they’ve become part of almost every aspect of our lives. From children’s toys to food packaging, plastic materials are a ubiquitous part of 21st-century life. In fact, in roughly 70 years, there has been 8.3 billion metric tons of plastic produced, with around 6.3 billion metric tons of that becoming waste.

And only 9% of that waste has been recycled.

There’s a variety of reasons for this, and while our plastic waste continues to grow, advances in technology and changes to the way we consume are helping to make it more efficient and effective.

Plastic recycling is extremely important, both as a method to deal with our existing waste and as a component of both circular economy and zero-waste systems that aim to reduce waste generation and increase sustainability. There are social, environmental, and economic consequences surrounding our current waste generation and disposal habits, and whether that is the issue of microplastics or an estimated $2.5 trillion in damage and lost resources to fisheries, aquaculture, recreational activities, and global wellbeing, the impact is no longer in doubt.

However, meeting the challenges posed by plastics is not simple, and there exists a lack of awareness surrounding the plastic waste problem. Despite the fact that potential issues were first flagged in the 1960s, historically, there has been a lot of pushback against implementing real change—mainly from the plastics industry itself. Recently, the tide seems to be turning on this issue as more people look for sustainable options and educate themselves about why plastic recycling is important.

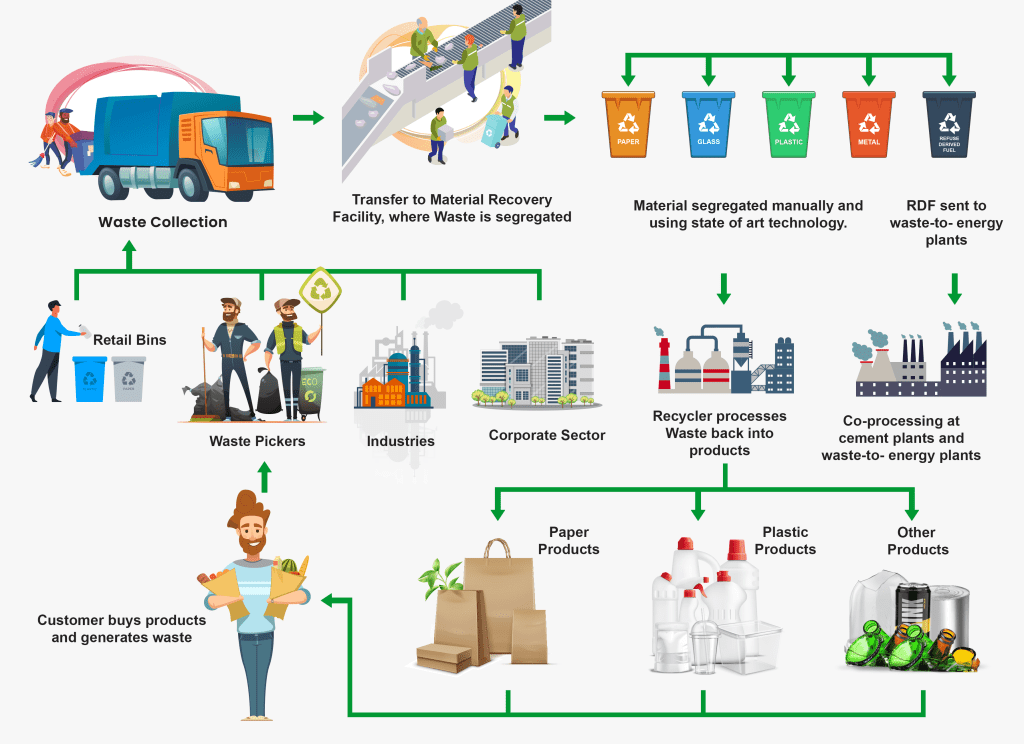

The first step in the mechanical recycling process is the collection of post-consumer materials from homes, businesses, and institutions. This can be done by either local government or private companies, with the latter often a popular option for businesses. Another option is taking plastics to communal collection points such as designated recycling bins or facilities. This may be as simple as a bottle bank on a street corner or as complex as a local waste site with large areas for various recyclable and non-recyclable municipal solid waste (MSW).

The next step in the plastic recycling process is sorting. There are several different types of plastic (see below), which need to be separated from each other by recyclers. Further to that, plastics might be sorted by other properties such as color, thickness, and use. This is done by machines at the recycling plant and is an important step to increase the efficiency of plants and avoid the contamination of end products.

Washing is a crucial step in the plastic recycling process since it removes some of the impurities that can impede the operation, or completely ruin a batch of recycled plastic. The impurities targeted in this step commonly include things such as product labels and adhesives as well as dirt and food residue. While plastic is often washed at this stage, it is important to remember that this doesn’t take away from the importance of ensuring plastics are as free from impurities as possible before disposal and collection.

The plastic is then fed into shredders, which break it down into much smaller pieces. These smaller pieces, unlike formed plastic products, can be processed in the next stages for reuse. Additionally, the resized plastic pieces can be used for other applications without further processing, such as an additive within asphalt or simply sold as a raw material. Breaking down the plastic into smaller pieces also allows for any remaining impurities to be found. This is especially true of contaminants such as metal, which may not have been removed by washing but can be easily collected with a magnet at this stage.

Here, the plastic pieces are tested for their class and quality. First, they are segregated based on density, which is tested by floating the particles of plastic in a container of water. This is followed by a test for what is known as the “air classification”, which determines the thickness of the plastic pieces. It is done by placing the shredded plastic into a wind tunnel, with thinner pieces floating while larger/thicker pieces stay at the bottom.

This final plastic recycling process step is where the particles of shredded plastic are transformed into a usable product for manufactures. The shredded plastic is melted and crushed together to form pellets. It is worth noting that it is not always possible to compound all types, classification, and qualities of plastic at a single plant, so different grades of plastic are sometimes sent to other recycling facilities for this final step.

Help Line: 1800 233 3002 Contact: (0261) 2223002

info@eco-vision.co.in

hr@eco-vision.co.in

Survey No.12-13, Near Torrent Power Sub Station, Bhatar - Bamroli Road, Bhatar, Surat - 395017 (Gujarat)